Capsule Filling Sealing Machine Series

We specialize in manufacturing

pharmaceutical packaging machine

for

pharmaceutical, biotechnology and food factory

..etc. Our machine fill

powder,

granule / pellet, liquid

into

hard capsule instead of soft capsule products.

Applicable

industry:Pharmacy,

Biotechnology, Health Supplements, Nutritional

Supplements, natural food…etc.

Capsule Filling Sealing

Machine Series include

Semi-Automatic

Capsule Filling

Machine,

Automatic Capsule Filling Machine,

Capsule/ Tablet Inspection

Machine, Capsule Polishing

Machine…etc.

|

|

|

|

|

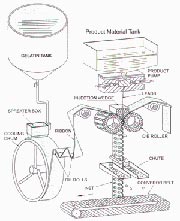

The is a fully

automatic capsule

filling machine with

capsule orientation,

opening the capsule,

powder filling, and

closing the

capsules. This

machine can be

filled on capsules

from sizes #00 to

#4, can feed

different types of

powder, and can also

fill granules &

pellets. Different

filling weights can

be adjustable

without changing

parts. This machine

can filled medical

powder, health food,

inhalant micronized

powder, natural

food, and

complicated powder

materials.

Max. Capacity:

50,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

KDF-6L Capsule

Liquid Filling

Machine equips the

servo control

system.

This machine can

fill liquid (oil

base) for hard

capsules, and adjust

filling volume by

the servo control

system. This machine

could equip the

filling units for

granules, micro

capsules or micro

tablets as options

for the best value

to verity functions

in one machine for

Pharmaceuticals,

Health supplements,

Nutrition,

Chemistry, Oil

industries.

Max. Capacity:

30,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

Capsule sealing

machine could seal the joint between the cap and

body of hard

capsules after it being filled with the products

(powder, liquid…) by a capsule

filling machine. The capsules being sealed can

contributing to product stability

and providing tamper evidence, and also prevents

capsules being opened or

leakage of liquid, powder or odor.

Max. Capacity:

30,000 Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

KWANG DAH has

specialized in design and manufacture of capsule

series machines since 1971.

Automatic Capsule Filling Machine has been

designed and developed to fill hard gelatin

capsules with powder or pellets. It is an extremely

durable and reliable machine that fills dosages

to the highest accuracy. It can be applicable to the

widest range of capsules at all sizes and to all

manufacturers and guarantee the integrity of all

capsules.

KDF-9 Max. Capacity: 72,000 Capsules/Hour.

KDF-18 Max. Capacity: 120,000 Capsules/Hour

|

|

|

|

| |

|

|

|

Semi-Auto Capsule Filling Machine (Horizontal Type) |

|

After KD's accumulated production experiences in

manufacturing several thousand sets of KDF-2

Vertical Closing Filling machine, KD developed the

latest KDF-2H can operates more efficiently and

smoothly without damaging the capsules.

This machine filled on powder and can also filled

on granules and pellets into the capsules.

This machine can filled medical

powder, health food, natural food, and complicated

powder materials.

Max. Capacity: 25,000 Capsules/Hour.

|

|

|

|

| |

|

|

|

Semi-Auto Capsule Filling Machine (Horizontal Type) |

|

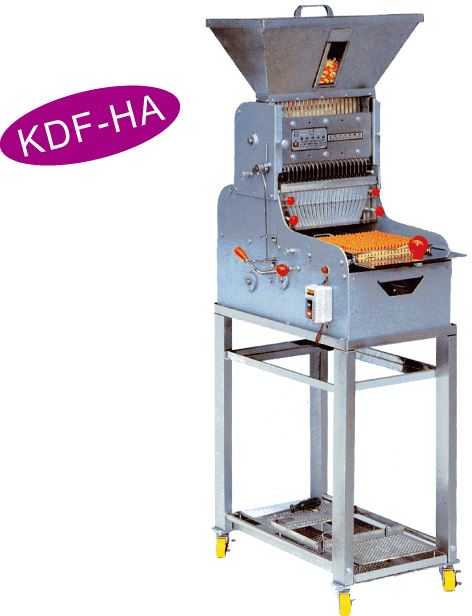

This equipment is a new model

horizontal semi-automatic capsule filling machine KDF-2HA

developed by Kwang Dah.

This model can choose the number of turns and speed when

filling, and the operation is simpler, also more accurate and

Safe, for filling powders and granules (round granules) with

good fluidity, greatly improving its efficiency and reducing

capsule loss rate. In addition, it is easier to clean and

maintain and meet the requirements of cG.M.P. and PIC/S.

Max. Capacity: 25,000 Capsules/Hour.

|

|

|

|

| |

|

|

|

Vertical Semi-Automatic Capsule Filling Machine (Discontinued) |

|

The

KDF-2 is the most popular and economical

semi-automatic capsule's filling machine. This

machine can fill on capsules from sizes #00 to #4,

Different filling weights can be adjustable without

changing parts. It can feed

different types of powder and can also fill granules

& pellets. This machine can filled medical powder,

health food, natural food, and complicated powder

materials. The only machine in the world that can

fills on the capsule with more weights.

Max. Capacity: 25,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the capsules

surface, through mechanically roating brush and

attraction of vacuum to make out the external

powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour.

|

|

|

|

|

KDI-1

|

|

This KDI-1 is a tablet & capsule inspection machine

that is designed and used for inspecting capsules or

tablets that are spotty, broken, or not standard by

vision through mechanically rotating the capsule

over 360 degrees or turning the tablet from one side

to the other side. The inspector can easily take out

any bad capsule or tablet and collect them.

Max. Capacity: 70,000 PCS./Hour.

|

|

|

| |

|

|

|

Automatic Soft Gelatine

Encapsulation Machine |

|

KDE-300 Fully Automatic Soft Gelatin Encapsulation

Machine is the most popular Soft Gelatin Capsule

making machine in the world; and more than 90% of

soft gelatin capsules in the world are produced by

this kind of machine, which had been modified by QUI

technics and experiences to the KDE-300.

Max. Capacity:

45,200 PCS./Hour. (ROUND 3)

32,500 PCS./Hour. (OBLONG 3)

32,760 PCS./Hour. (OVAL 3)

|

|

|

|

| |

|

|

|

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the capsules

surface, through mechanically roating brush and

attraction of vacuum to make out the external

powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour

|

|

|

|

|

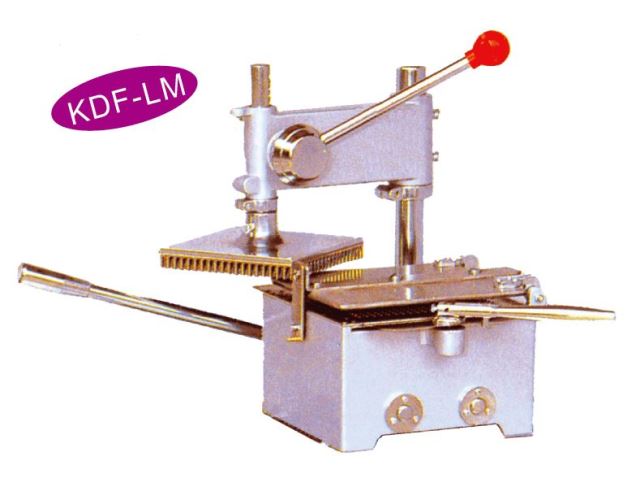

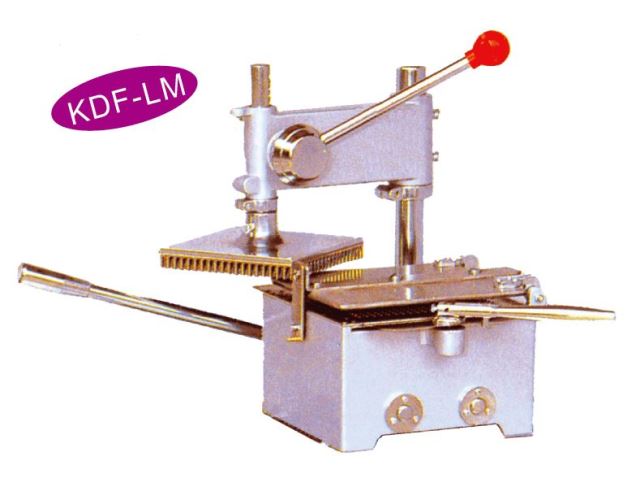

KDF-LM

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the

capsules surface, through mechanically roating brush

and attraction of vacuum to make out the

external powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour

|

|

|

|

|