|

Products Profile

|

Capsule Filling Machine Series |

|

|

|

|

|

The is a fully

automatic capsule

filling machine with

capsule orientation,

opening the capsule,

powder filling, and

closing the

capsules. This

machine can be

filled on capsules

from sizes #00 to

#4, can feed

different types of

powder, and can also

fill granules &

pellets. Different

filling weights can

be adjustable

without changing

parts. This machine

can filled medical

powder, health food,

inhalant micronized

powder, natural

food, and

complicated powder

materials.

Max. Capacity:

50,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

KDF-6L Capsule

Liquid Filling

Machine equips the

servo control

system.

This machine can

fill liquid (oil

base) for hard

capsules, and adjust

filling volume by

the servo control

system. This machine

could equip the

filling units for

granules, micro

capsules or micro

tablets as options

for the best value

to verity functions

in one machine for

Pharmaceuticals,

Health supplements,

Nutrition,

Chemistry, Oil

industries.

Max. Capacity:

30,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

Capsule sealing

machine could seal the joint between the cap and

body of hard

capsules after it being filled with the products

(powder, liquid…) by a capsule

filling machine. The capsules being sealed can

contributing to product stability

and providing tamper evidence, and also prevents

capsules being opened or

leakage of liquid, powder or odor.

Max. Capacity:

30,000 Capsules/Hour.

|

|

|

|

|

| |

|

|

|

|

|

KWANG DAH has

specialized in design and manufacture of capsule

series machines since 1971.

Automatic Capsule Filling Machine has been

designed and developed to fill hard gelatin

capsules with powder or pellets. It is an extremely

durable and reliable machine that fills dosages

to the highest accuracy. It can be applicable to the

widest range of capsules at all sizes and to all

manufacturers and guarantee the integrity of all

capsules.

KDF-9 Max. Capacity: 72,000 Capsules/Hour.

KDF-18 Max. Capacity: 120,000 Capsules/Hour

|

|

|

|

| |

|

|

|

Semi-Auto Capsule Filling Machine (Horizontal Type) |

|

After KD's accumulated production experiences in

manufacturing several thousand sets of KDF-2

Vertical Closing Filling machine, KD developed the

latest KDF-2H can operates more efficiently and

smoothly without damaging the capsules.

This machine filled on powder and can also filled

on granules and pellets into the capsules.

This machine can filled medical

powder, health food, natural food, and complicated

powder materials.

Max. Capacity: 25,000 Capsules/Hour.

|

|

|

|

| |

|

|

|

Semi-Auto Capsule Filling Machine (Horizontal Type) |

|

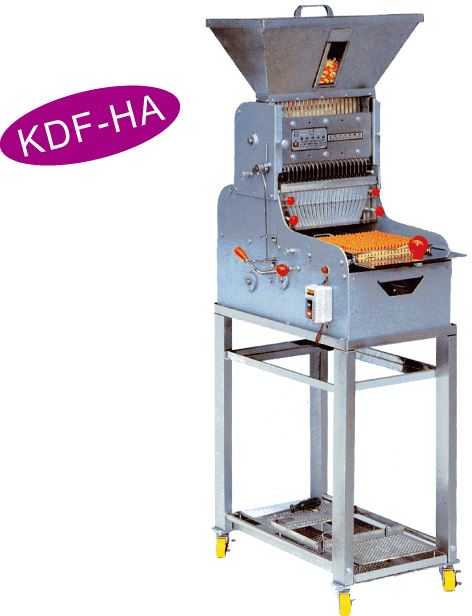

This equipment is a new model

horizontal semi-automatic capsule filling machine KDF-2HA

developed by Kwang Dah.

This model can choose the number of turns and speed when

filling, and the operation is simpler, also more accurate and

Safe, for filling powders and granules (round granules) with

good fluidity, greatly improving its efficiency and reducing

capsule loss rate. In addition, it is easier to clean and

maintain and meet the requirements of cG.M.P. and PIC/S.

Max. Capacity: 25,000 Capsules/Hour.

|

|

|

|

| |

|

|

|

Vertical Semi-Automatic Capsule Filling Machine (Discontinued) |

|

The

KDF-2 is the most popular and economical

semi-automatic capsule's filling machine. This

machine can fill on capsules from sizes #00 to #4,

Different filling weights can be adjustable without

changing parts. It can feed

different types of powder and can also fill granules

& pellets. This machine can filled medical powder,

health food, natural food, and complicated powder

materials. The only machine in the world that can

fills on the capsule with more weights.

Max. Capacity: 25,000

Capsules/Hour.

|

|

|

|

| |

|

|

|

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the capsules

surface, through mechanically roating brush and

attraction of vacuum to make out the external

powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour.

|

|

|

|

|

KDI-1

|

|

This KDI-1 is a tablet & capsule inspection machine

that is designed and used for inspecting capsules or

tablets that are spotty, broken, or not standard by

vision through mechanically rotating the capsule

over 360 degrees or turning the tablet from one side

to the other side. The inspector can easily take out

any bad capsule or tablet and collect them.

Max. Capacity: 70,000 PCS./Hour.

|

|

|

|

| |

|

|

|

Automatic Soft Gelatine

Encapsulation Machine |

|

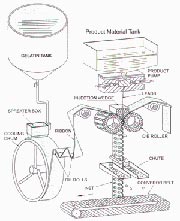

KDE-300 Fully Automatic Soft Gelatin Encapsulation

Machine is the most popular Soft Gelatin Capsule

making machine in the world; and more than 90% of

soft gelatin capsules in the world are produced by

this kind of machine, which had been modified by QUI

technics and experiences to the KDE-300.

Max. Capacity:

45,200 PCS./Hour. (ROUND 3)

32,500 PCS./Hour. (OBLONG 3)

32,760 PCS./Hour. (OVAL 3)

|

|

|

|

| |

|

|

|

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the capsules

surface, through mechanically roating brush and

attraction of vacuum to make out the external

powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour

|

|

|

|

|

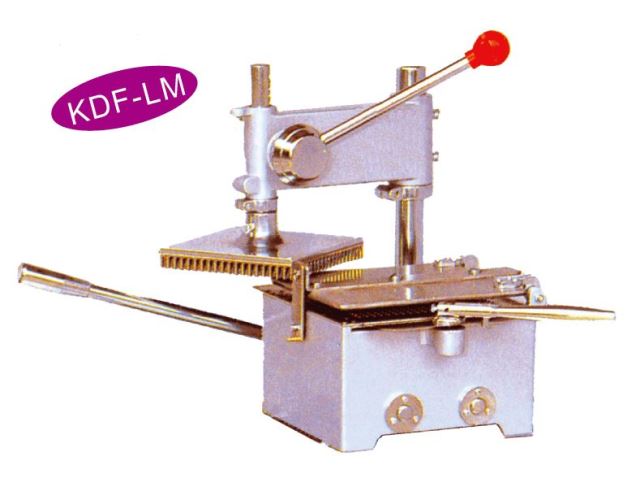

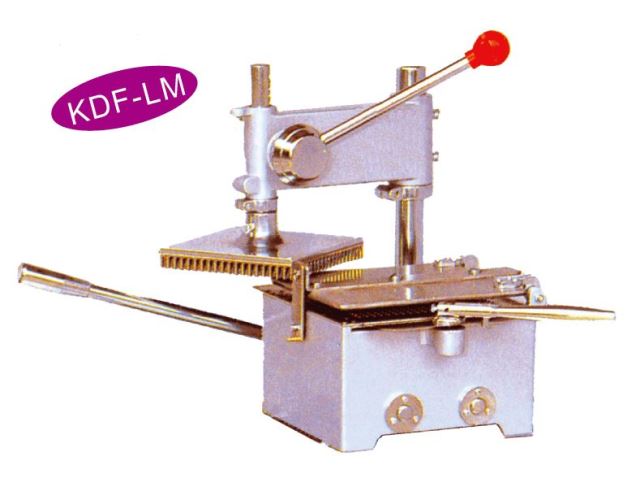

KDF-LM

|

|

This polishing machine is used after capsules were

filled for cleaning the powder attached on the

capsules surface, through mechanically roating brush

and attraction of vacuum to make out the

external powder.

Optional: can reject unfilled capsule.

Max. Capacity: 400,000 Capsules/Hour

|

|

|

| |

| |

|

|

|

|

|

Multi-Tray

Tablet & Capsule Counter |

|

The KDC-212 is a multi-tray (12 channels)

counting machine that can accurately counts and

fills all shapes of tablets, capsules, caplets, soft

capsules and transparent products without change

parts.

This machine is equip with dust compensator and

sensor sensitivity that automatically self-adjust to

offset the gradual accumulation of powder on the

sensor window.

Max. Capacity: 850,000 Tablets/Hour.

|

|

|

|

|

|

|

|

|

Tablet &

Capsule Counter |

|

This KDC-101 is the most popular and

economical counting machine for pharmaceutical

product in the world.

It aligns the capsules or tablets passing thru

accurate sensor for accurate counting then

filling into bottles. It accurately counts and

fills all shapes of capsules, tablets, soft

capsules, caplets, or transparent products. This

machine is equip with dust compensator & sensor

sensitivity that automatically self-adjust to

offset gradual accumulation of powder on the

sensor window.

Max. Capacity: 160,000 Tablets/Hour.

|

|

|

|

|

|

|

|

|

Automatic

Counting & Filling Machine |

|

This KDV-3 is an automatic counting and

containers feeding machine that accurately

counts all shapes of capsules, tablets, and

other similarproducts.

This machine can be connected into one

production line including automatic capping

machine, labeling machine...etc.

Max. Capacity: 160,000 Tablets/Hour.

|

|

|

|

|

|

|

|

Automatic Counting & Capping Machine

The KDV-5 is an

automatic

counting, container feeding, and

capping machine.

It consists of two sets of batch

counters

( Model:KDC-101 ) with

turntable, conveyor & capping

machine ( Model: KDK-500 ).

Max. Capacity: 160,000

Tablets/Hour.

|

|

|

|

|

|

|

|

Automatic

Counting & Filling Machine

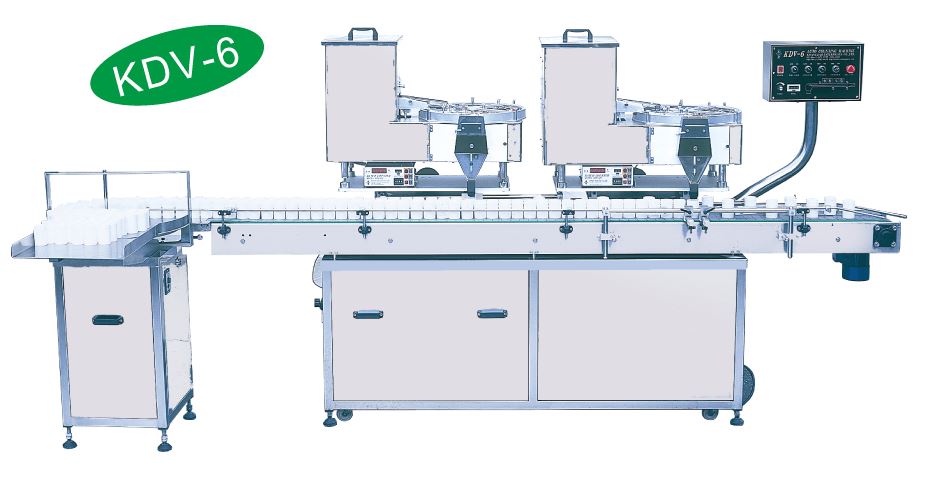

The KDV-6 is an

automatic counting, container

feeding, and capping machine. It

consists of two sets of batch

counters ( Model: KDC-101 ) with

turntable, conveyor & capping

machine

( Model: KDK-500 ).

Max. Capacity: 320,000

Tablets/Hour.

|

|

|

|

|

|

|

|

|

Automatic Counting & Capping Machine

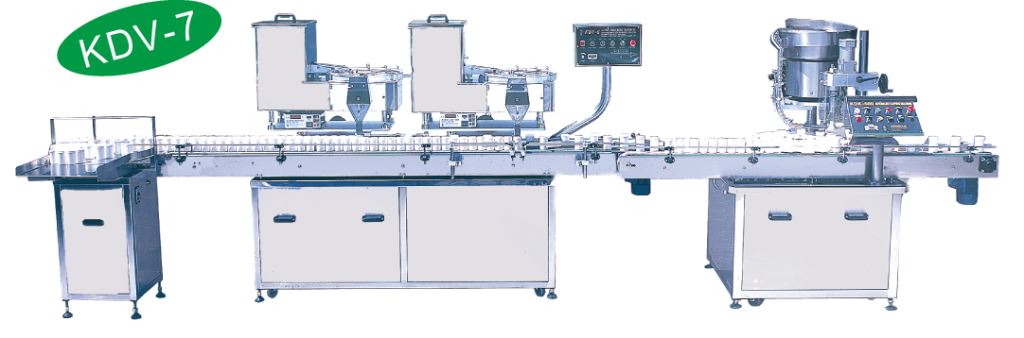

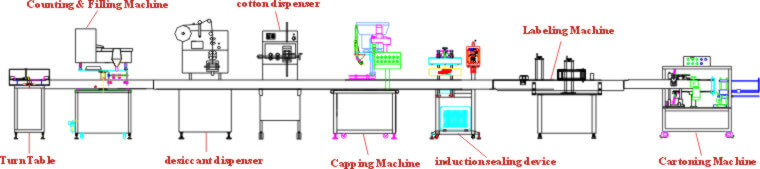

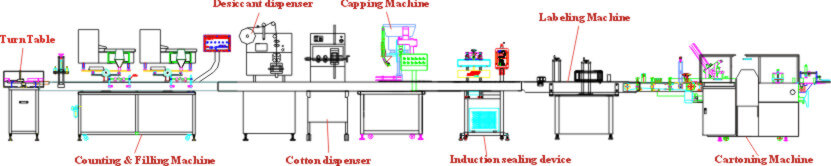

The

KDV-7 is an automatic

counting, container feeding, and capping

machine.

It consists of two sets of batch counters (

Model:KDC-101 ) with turntable, conveyor &

capping machine ( Model: KDK-500 ).

Max. Capacity: 320,000 Tablets/Hour.

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

KDB-120

|

|

This KDB-120 is an automatic blister packing (Press

Through Package (PTP)) machine that

fully automatically heating the PVC then

forming, feeding, sealing, embossing,

perforating & trimming.

It can be used for the pharmaceutical packing

(tablets, capsules, pills, and etc...), food and

other similar products packing.

This machine waste no materials because no

scrap in between two blisters.

The expiration of the cross-net type sealing

is 4 times longer than the traditional dot-type

sealing (plate-type).

Max. Capacity: 200 Blisters/Minute.

|

|

|

|

|

KDB-120ALU

|

|

This KDB-120 ALU

production procedure is the same as KDB-120

(PVC-ALU type) & it can also produce ALU-ALU. It

uses cold extrusion, forming, feeding, sealing,

embossing, perforating, and finally trimming.

This machine waste no materials because no scrap

in between two blisters.

This machine specially designed for the ALU/ALU

product for the purpose of better preservation.

(preventing air of getting into the blister

packs & preservation from exposure to light

rays.)

Max. Capacity: 100

Blisters/Minute. (for ALU/ALU)

|

|

|

|

|

|

|

|

|

|

This KDB-240 is a high-speed double lines automatic

blister packing (Press Through Package (PTP))

machine.

It automatically heats the PVC then forming,

feeding, sealing, embossing, perforating & trimming.

It can be used for the pharmaceutical packing

(tablets, capsules, pills, and etc...), food and

other similar products packing.

Max. Capacity:400 Blisters/Minute.

|

|

|

|

|

|

|

|

This KDS-800 is a strips packing machine that feed

capsules or tablet in-between two aluminum foils

then sealing, slitting, cutting and finally the

finished products.

This sealing method can prevent humidity, light

source and better than the blister packing.

Max. Capacity: 1,000 Tablets/Minute.

|

|

|

|

| |

|

|

|

KDM-920

|

|

The KDM-920 is a compact combination set of

automatic blister packing machine

( Model: KDB-120 ) & automatic cartoning machine

( Model: KDM-900 ).

This machine starts its production of blister

products then inserted into the automatic

cartoning machine for final packing. Bottle

types of products are available(Optional ).

Max. Capacity: 100 Cartons/Minute.

|

|

|

|

| |

|

|

|

KDB-50T

|

|

The new, compact Mini PRESS-OUT Universal is a

small, yet flexible, hand-fed deblistering machine

for small batches. It guarantees 100% recovery

rates, even for fragile product or problem blisters.

The Mini PRESS-OUT Universal handles any blister

material using only a two-part toolset.

Tool-less changeover is less than 1 minute.

Max. Capacity: 30 Blisters/Minute.

|

|

|

|

|

|

KDB-50 |

|

The new, compact Mini PRESS-OUT Universal is a

small, yet flexible, hand-fed deblistering machine

for small batches. It guarantees 100% recovery

rates, even for fragile product or problem blisters.

The Mini PRESS-OUT Universal handles any blister

material using only a two-part toolset.

Tool-less changeover is less than 1 minute.

Max. Capacity: 30 Blisters/Minute.

|

|

|

|

| |

|

|

Aseptic

Filling, Stoppering & Closing Machine (Vial /

Eye-Drop) |

|

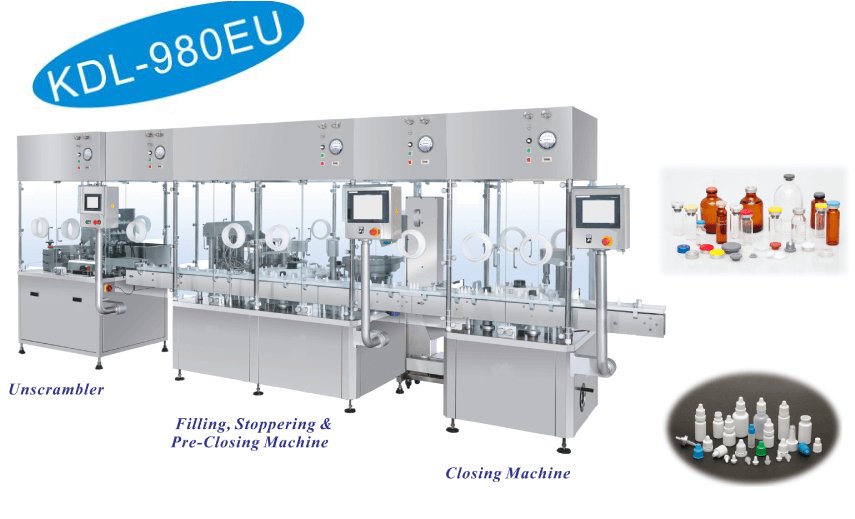

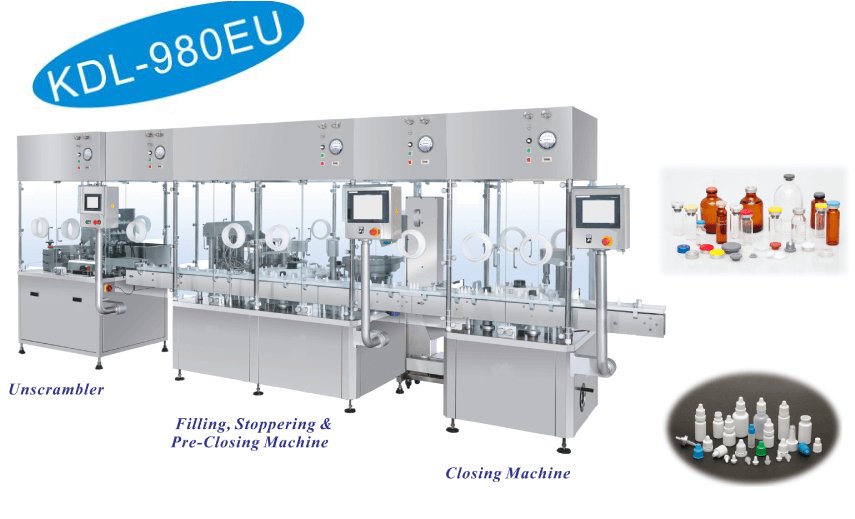

KDL-980EU |

Kwang Dah

accumulated a lot of producing experience in liquid

filling, stoppering & closing machine for many

years. We developed the In-Line Aseptic Preparation

Machine which is designed for vials & eye-drops.

It can be equipped with unscrambler, nitrogen

filling, liquid filling, stoppering, pre-closing, &

closing machine become a complete In-Line eye drop

processing machine.

It also can equipped with turn table, nitrogen

filling, liquid filling, rubber stoppering &

aluminum cap closing machine become a complete

In-Line vials processing machine.

In

accordance with PIC/S GMP & Aseptic Preparation

requirements, machine using many high precision

servo controllers & combined PLC & HMI for

production operation & adjustment, therefore“ONE

TOUCH” will automatically adjust the conditions of

production during production operation or adjusting,

it is a user-friendly with high-efficiency machines.

Max. Capacity: 100 Bottles/Minute.

|

|

|

|

|

|

|

|

|

This KDL-980 series machine is an automatic

liquid filling, plugging, & capping machine.

It is capable of filling small containers

(2cc to 60cc) including eyedrops, vials,

cosmetics, & other types containers.

This monoblock type machine consist of bottle

feeding, nitrogen air filling, liquid filling,

plugging, and capping.

Max. Capacity: 50~100 Bottles/Minute.

|

|

|

|

|

|

|

|

This KDL-980SG machine is an automatic liquid

filling, plugging & capping machine.

It is capable of filling small containers ( 2cc

to 100cc ) including eye-drops, vials,

cosmetics, & other types containers. This

monoblock type machine consist of bottle

feeding, nitrogen air filling, liquid filling,

plugging, and capping.

Suitable for pharmaceutical, cosmetic,

nutrition, Food industries etc.

Max. Capacity: 50~100 Bottles/Minute.

|

|

|

|

|

|

|

|

|

KDL-950

|

|

The KDL-950 is a compact combination set of

liquid filling & capping machine. Accurate

volumetric filling designed by stainless steel

cylindrical piston. This machine can filled

pharmaceutical or chemical liquids, lotions,

oils, cosmetics, beverages, syrups, sauces, etc.

Max. Capacity: 60 Bottles/Minute.

|

|

|

|

|

|

KDL-700

|

|

This KDL-700 is a machine that was specially

developed in order to fill high viscosity liquid

products such as shampoo, shower gel, lotions,

oils (motor oil & cooking oil), etc.

This machine can also fill on low viscosity

liquid products.

Max. Capacity: 60 Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

|

This

KDL-650 is a liquid filling machine that is a

volumetric filling designed by stainless steel

cylindrical piston.

This machine can filled pharmaceutical or

chemical liquids, oils, beverages, etc.

Max. Capacity: 60

Bottles/Minute.

...more |

|

|

|

|

|

|

|

|

|

The KDL-600 is a liquid filling that is a level

control by diaphragm pump not necessary to

adjust machine when filling volume changed.

This machine can fill on pharmaceutical &

chemical liquids, cosmetics, oils, sauces, etc.

Max. Capacity: 60 Bottles/Minute.

...more |

|

|

|

|

|

|

|

|

|

|

The KDL-250 is a two-tube type semi-automatic

volumetric liquid filling machine.

It is applicable on all types of chemicals or

pharmaceuticals liquid products, oils,

beverages, lotions, sauces, etc.

Max. Capacity: 40 Bottles/Minute.

|

|

|

|

|

|

|

|

*Uniform filling level suitable for glass or

hard plastic bottles.

*Suitable for various shape & different

size containers.

*All stainless construction meeting

G.M.P. requirements.

Max. Capacity: 30 Bottles/Minute.

|

|

|

|

|

|

|

|

|

Cartoning

Machine Series |

|

|

|

Semi-Automatic Cartoning Machine |

|

The KDM-300 is an intermittent vertical

cartoner that automatically open/fold

cartons,

manual insertion of products into the carton

and automatically closes the carton.

This cartoner can handle wide range of

cartons to accept various bottles, blisters,

pouches, sachets, tubes, etc.

Hot-Melt Glue Sealing Cartoner is available

under Model: KDM-300H

Max. Capacity: 60 Cartons/Minute.

|

|

|

|

|

|

|

|

|

Automatic Cartoning Machine |

|

The KDM-300A is a fully automatic

intermittent vertical cartoner that

automatically open/fold cartons, coding,

insert leaflet into the cartons, in feed

products and then automatically close the

carton. The product range is almost

unlimited and encompassing including bottle,

tubes, etc.

Hot-Melt Glue Sealing Cartoner is available

under Model: KDM-300A

Max. Capacity: 60 Cartons/Minute.

|

|

|

|

|

|

|

|

|

Automatic Cartoning Machine |

|

The KDM-900 is a fully automatic

intermittent horizontal cartoner that

automatically open/fold cartons, infeed

products, insert leaflet into the cartons,

coding and then automatically close

the carton.

This cartoner can handle wide range of

cartons to accept various bottles, blister

packs, tubes, etc.

Hot-Melt Glue Sealing Cartoner is also

available under Model: KDM-900H

Max. Capacity: 100 Cartons/Minute.

|

|

|

|

| |

|

|

|

Other Machine Series |

|

|

|

|

|

The KDJ-200 is an automatic self-adhesive

type wrap-around labeling machine. It can be

applied on different sizes of labels onto

the round shape bottles.

Max. Capacity: 200

Bottles/Minute.

|

|

|

|

|

|

|

|

The KDJ-300 is an automatic resign glue type

labeling machine. It is a applicable onto

all round shape bottles.

Max. Capacity: 60

Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

|

The KDK-100 is a semi-automatic capping

machine.

The friction clutch can be adjusted for the

tightness of different sizes of caps.

It is designed for press-on type and screw

type caps.

Max. Capacity: 30 Bottles/Minute.

|

|

|

|

|

|

|

|

The KDK-150 is a semi-automatic capping

machine that operates on screw type,

press-on, flip-off, pilfer-proof, and thread

screw type (aluminum caps).

This machine is equip with adjustable cap

tightener and simplified height adjuster.

Max. Capacity: 30 Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

|

The KDK-500 is a machine that automatically

infeed caps onto bottles then automatically

capping the bottles. This machine operates

on different

sizes of bottles with different types of

caps: screw type, press-on, flip-off,

pilfer-proof, & thread screw type (aluminum

caps).

Max. Capacity: 60 Bottles/Minute.

|

|

|

|

|

|

|

|

The KDL-280 is a semi-automatic ointment's

filling machine.

It is applicable on filling ointment, creamy

products cosmetic products, etc.

Max. Capacity: 30 Bottles/Minute.

|

|

|

|

|

|

|

|

|

|

|

The KDFC-200 is a

Powder Filling Plugging Capping Machine.

Designed for

automatic packing of free-flowing powder

materials such as granules, powder,

chemicals, Chinese &Western medicine powder

and coffee powder etc.

Max. Capacity: 20~35 Bottles/Minute.

|

|

|

|

|

|

|

|

|

Packaging

Material

|

|

|

|

|

|

Cylindric desiccant is a cylindric-shaped

plastic housing into which silica gel is filled

, adn covering a ventilated card on the top.The

moisture adsorption capability of this cylindric

desiccant can replace 100% of the bag desiccat

thus making the product to be more better

appearance , clean and the packing to be more

beautiful for enhancing the added value of the

product. On the other hand , it will show the

high quality of products , and enhance

enterprise image .

|

|

|

|

|

|

|

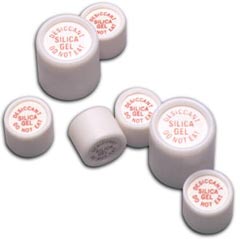

Desiccant inserts are small

components filled with desiccant canister

designed to rest in the screw-on caps of bottle

containers, including those designed with

tamper-evident and child-resistant features.

|

|

|

|

|

|

|

|

|

|

|

|

In cooperating with the

pharmaceutical factory cGMP, we provide the

clients the most appropriate and practical

products and the convenient and satisfactory

service.

In response to the governments's enforcing cGMP

system, and elevating the pharmaceutical

standard in Taiwan,

|

|

|

|

|

|

|

|

|

Powder

Processing Machine |

|

|

|

|

|

This machine can be divided into wet-type or dry-type

granulation.

Wet-type granulation needs to add water or solvent as the

adhesive during the granulation process.

Thus the drying process is

essential after the granulation process.

Dry-type granulation doesn't need to add to the liquid but it

can add to the binder or lubricant and as a result, the drying

process is not required.

It can turn some low-density, low-specific gravity, and bad-flow

materials or water-sensitive drugs into high-density,

high-specific gravity, good-flow materials or the finished

product which can be filled into a capsule or formed as a

tablet.

|

|

|

|

|

|

|

|

|

|

High efficiency coater is mainly used for tablet and candy to carry out organic thin film

coating, water soluble thin film coating, sugar-coating and chocolate in pharmaceutical and

foodstuff industry. It is electromechanical integration coating equipment and conforms to

the requirement of cGMP Information: Peristaltic pump with constant pressure variable,

eliminate reflux pipe.

|

|

|

|

|

|

Top spray type:

Drying wet

granule or powder;

granulation

and drying of spraying binder on tiny

powder.

Bottom spray type :

Spray suspension on pellet

or film / enteric

coating.

|

|

|

|

|

|

|

|

|

|

For Dryer /

Granulation in batch mode, the dry starting product is placed in

the product container. Here it is mixed vigorously in the heated

gas stream, held in suspension and agglomerated/granulated by

spraying with a suitable bonding material. The product is then

dried to the required end moisture content with high heat and

material transition coefficients.

|

|

|

|

|

SUPER MIXER /

GRANULATOR |

|

|

|

The super chip

mixer in reference is a new and instant mixer applicable to the

mixing of powder dampened kneading and granulation and simple

operation as well as easy cleaning meet the cGMP requirements.

Powder is Charged into bowl of SMG and wetted by a liquid or a

melt sprayed from the top nozzle. At the same time, the material

is vigorously mixed by a mixer and chopped by a chopper.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cone milling is a gentle, low energy size reduction mill ideal for fatty, heat sensitive,

sticky, moist or fragile products. It alleviates traditional milling problems of noise, dust

and heat generation as ideal for use in food and pharmaceutical applications.

|

|

|

|

|

|

|

|

Power mill (Multi Mill)is widely used for wet and dry granulation, pulverization etc., in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colors, Dyestuff, Food products etc. It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides,

Plastics and Resins Industries.

|

|

|

|

|

|

|

|

|

|

|

|

Appliciation

Pharmaceuticals,

foods, chemicals, feeds, and agricultural products.

|

|

|

|

|

|

|

Appliciation

Pharmaceutical: ointment.

Cosmetic: cream, toothpaste, etc.

|

|

|

|

|

|

|

|

|

|

|

Cone milling is a gentle, low energy size reduction mill ideal for fatty, heat sensitive,

sticky, moist or fragile products. It alleviates traditional milling problems of noise, dust

and heat generation as ideal for use in food and pharmaceutical applications.

|

|

|

|

|

|

|

|

|

|

Other

Manufacturer Machine |

|

|

|

|

Suitable For Box

Or Square, Rectangle Product Outer Film Over Wrapping.

|

|

|

|

|

|

|

Food Vacuum Packing. Medical Items

Packing. Blister Packing.

|

|

|

|

|

|

|

|

|

|

|

Use Vacuum Packing To Prolong The Product

Shelf Life.

|

|

|

|

|

|

|

|

Use Shrink Packing To Prevent Products From Dust, Moisture And

Thief.

|

|

|

|

|

|

|

|

|