KDB-120 Automatic

Blister Packaging Machine (ALU-ALU)

|

|

|

Alu/Alu blister packing machine KDB-120ALU(Automatic

Blister Packing Machine) is

specially designed for the ALU/ALU product for

the purpose of better preservation and

prevention of light rays. KDB-120ALU has similar

features with KDB-120 except it's formed by cold

extruding. It can also pack ALU/PVC's product.

Applicable

industry:Pharmacy,

Biotechnology, Health Supplements, Nutritional

Supplements, natural food…etc.

|

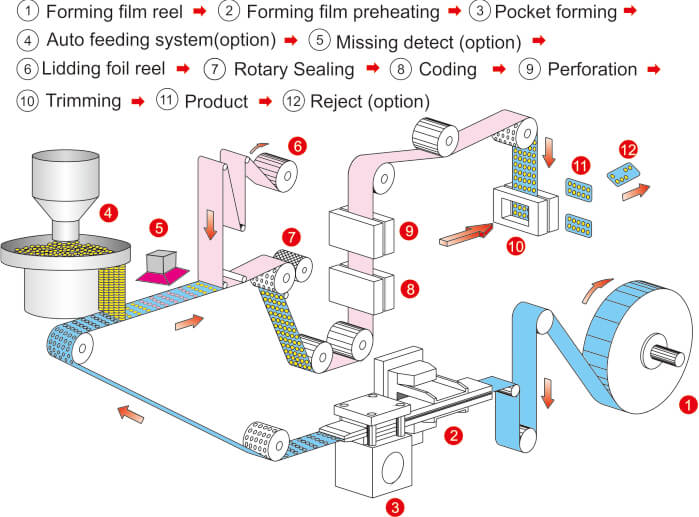

FLOW

CHART

KDB

MACHINE

Sealing

Line (cross-net type) |

|

TRADITIONAL

MACHINE

Sealing

Dot (plate type) |

|

|

|

|

Cross-net type roller,due to crossed net sealing is

capable of blocking the air completely and

prolonging medicine preservation about 4 times over

plate type sealing.

The cross-net type roller is composed of two

rollers compressed in a single line with a very

small contact area preventing hot air from getting

into the blister pockets,so medicine effectiveness

is unaffected. |

|

Dot type (plate-type)

Plate type uses dot-type sealing:air gets into the

medicine where there aren't dots and thus

shortens expiration.

Since the sealing area is larger and sealing time

longer, during the sealing process, hot air easily

gets into the blister pockets. This decreases the

effectiveness of the medicine. |

|

|

|

|

|

|

The machine adopts a no waste cut method, so no

wasted material is

produced. It can save

about 1/5 of material compared to traditional

types.

|

|

Plate-type

of triming wastes about 3-5 mm of material between

two blister and increases cost at the same time. |

|

OPTION |

|

|

|

|

Automatic Feeding Device

For Capsule & Tablet:

The capsule or tablet

can

be filled 100% automatically

into blister pocket by

vibrating feeder. |

|

|

|

Automatic orientation device

for capsule (capsule only):

Automatically fill the

two

piece hard capsule into the

blister pocket at same

direction by capsule

orientation structure. |

Brush Box feeder

Easy to feed all

diffent

kinds of products into the

blister pocket with brushes. |

|

Miss-Feeding Detecting

System:

Capable of detecting

miss-feeding blister by

detecting system.

|

|

FEATURES:

|

1.

|

Compact size with all function and fast

production. |

|

2.

|

Compressed air forming creates equivalent

blister pocket. |

|

3.

|

Continuous motion offers best filling

condition. |

|

4.

|

Equipped with trouble detection system which

displays where the trouble is. |

|

5.

|

The machine adopts a no waste trimming

method to save material. |

|

6.

|

It

is very easy to exchange all the size change

parts. It takes less than 30 minutes to

finish. |

|

7.

|

Main frame is covered with stainless steel.

This makes it easier to clean and meets

cG.M.P.

standard. |

|

8.

|

It

is neither noise nor creates public hazards

and it is easy to operate. |

|

9.

|

The expiration is about 4 times longer than

traditional dot-type sealing. |

|

|

TECHNICAL DATA

|

Model |

KDB-120

|

KDB-120ALU |

|

Output |

Max. 200 blisters/min |

Max. 100 blisters/min |

|

Forming/Material Width |

Max.140

mm |

|

Forming

Depth |

Max.12mm |

Max.9mm |

|

Formed

Area Available |

Max.146 x

125mm |

|

Reel

Diameter |

Forming

Material |

Max. Φ

400mm |

|

Lidding

Material |

Max. Φ

240mm |

|

Reel Core |

Φ 70 ~ Φ 76mm |

|

Power

Supply |

220V/380V

50HZ/60HZ 1 phase |

|

Power

Consumption |

7.2 KW |

8 KW |

|

Air

Consumption |

6 kgf/cm²

, 75 ∫/min |

|

Forming

Materials |

PVC,

PVC/PVDC

PVC/ACLAR, PP |

Aluminium

laminate,PVC,PP,

PVC/PVDC,PVC/ACLAR,

|

|

Lidding

Foil |

ALU/HARD,ALU/SOFT,ALU/PAPER,

ALU/POLYESTER,PP |

|

Machine Size (LxWxH) |

260x95x200 (cm) |

|

Packing

size (LxWxH) |

285x115x175 (cm) |

|

Gross

Weight |

1400kgs |

|

Net

Weight |

1000kgs |

◎ The specification, appearance and

dimensions shall be subject to change without

prior notice.

◎ Other KD machine series please browse our

website check to detail.

|

|

|

|