Powder Processing Machine

|

|

|

|

|

|

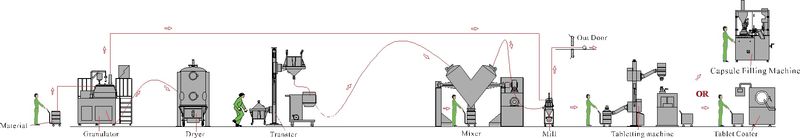

This machine can be divided into wet-type or dry-type

granulation.

Wet-type granulation needs to add water or solvent as the

adhesive during the granulation process.

Thus the drying process is essential after the granulation

process.

Dry-type granulation doesn't need to add to the liquid but it

can add to the binder or lubricant and as a result, the drying

process is not required.

It can turn some low-density, low-specific gravity, and bad-flow

materials or water-sensitive drugs into high-density,

high-specific gravity, good-flow materials or the finished

product which can be filled into a capsule or formed as a

tablet.

|

|

|

|

|

|

|

|

|

|

High efficiency coater is mainly used for tablet and candy to carry out organic thin film

coating, water soluble thin film coating, sugar-coating and chocolate in pharmaceutical and

foodstuff industry. It is electromechanical integration coating equipment and conforms to

the requirement of cGMP Information: Peristaltic pump with constant pressure variable,

eliminate reflux pipe.

|

|

|

|

|

|

Top spray type:

Drying wet

granule or powder;

granulation

and drying of spraying binder on

tiny

powder.

Bottom spray type :

Spray suspension on pellet

or film / enteric

coating.

|

|

|

|

|

|

|

|

|

|

For Dryer /

Granulation in batch mode, the dry starting product is placed in

the product container. Here it is mixed vigorously in the heated

gas stream, held in suspension and agglomerated/granulated by

spraying with a suitable bonding material. The product is then

dried to the required end moisture content with high heat and

material transition coefficients.

|

|

|

|

|

SUPER MIXER /

GRANULATOR |

|

|

|

The super chip

mixer in reference is a new and instant mixer applicable to the

mixing of powder dampened kneading and granulation and simple

operation as well as easy cleaning meet the cGMP requirements.

Powder is Charged into bowl of SMG and wetted by a liquid or a

melt sprayed from the top nozzle. At the same time, the material

is vigorously mixed by a mixer and chopped by a chopper.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cone milling is a gentle, low energy size reduction mill ideal for fatty, heat sensitive,

sticky, moist or fragile products. It alleviates traditional milling problems of noise, dust

and heat generation as ideal for use in food and pharmaceutical applications.

|

|

|

|

|

|

|

|

Power mill (Multi Mill)is widely used for wet and dry granulation, pulverization etc., in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colors, Dyestuff, Food products etc. It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides,

Plastics and Resins Industries.

|

|

|

|

|

|

|

|

|

|

|

|

Appliciation

Pharmaceuticals,

foods, chemicals, feeds, and agricultural products.

|

|

|

|

|

|

|

Appliciation

Pharmaceutical: ointment.

Cosmetic: cream, toothpaste, etc.

|

|

|

|

|

|

|

|

|

|

|

Cone milling is a gentle, low energy size reduction mill ideal for fatty, heat sensitive,

sticky, moist or fragile products. It alleviates traditional milling problems of noise, dust

and heat generation as ideal for use in food and pharmaceutical applications.

|

|

|

|

|

|

|