|

| Home>Main Products>Liquid Filling Machine Series |

Aseptic Filling, Stoppering & Closing Machine(Vial / Eye-Drop) |

|

KDW-U120 Unscrambler (For Eye-Drop Bottles)

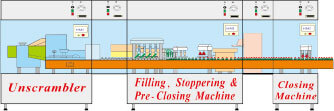

Aseptic Eye-Drop Processing Line

|

GENERAL: We developed the KDW-U120 (eye-drop unscrambler); it is designed for eye-drops…etc. It is suitable for small bottle as 2ml, 5ml, 10ml, 15ml & other small volume bottles.

FEATURES:

TECHNICAL DATA:

|

||||||||||||||||||||||||

|

KDK-500EU Closing Machine

|

GENERAL: In accordance with Aseptic preparation requirements, we developed the KDK-500EU (closing machine), it is suitable for vials, eye-drops & other aseptic products.

FEATURES:

TECHNICAL DATA:

|

|

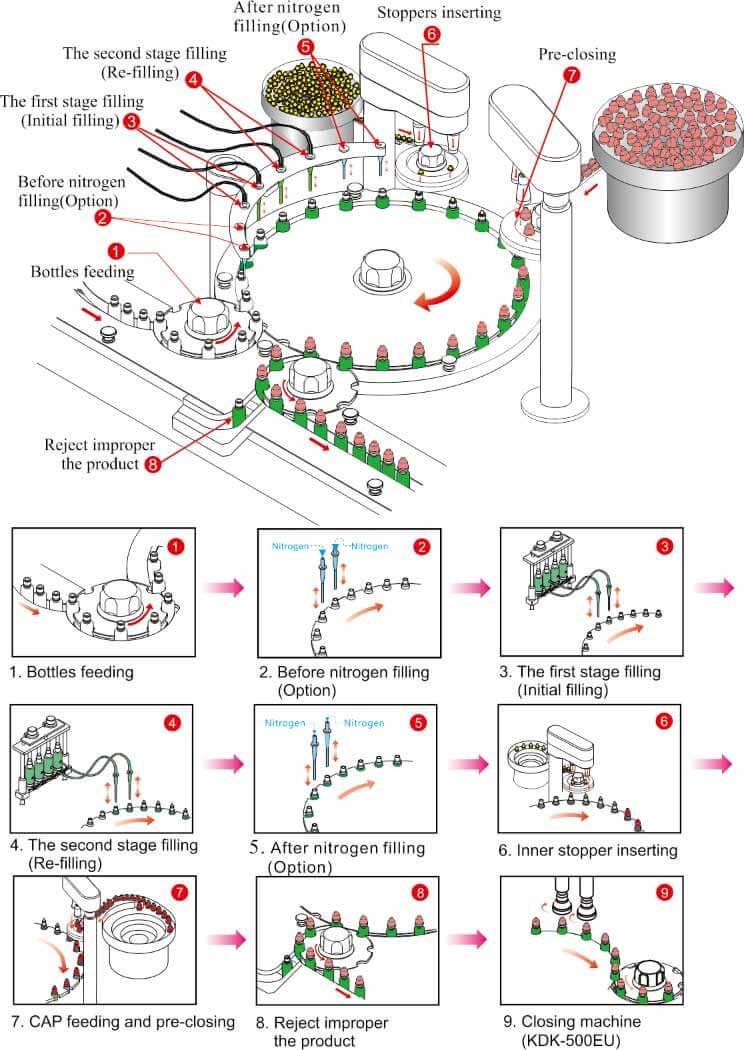

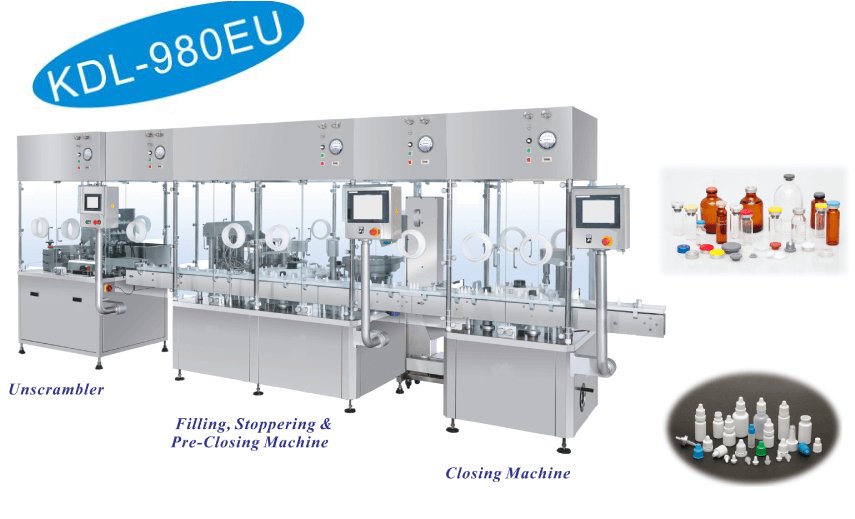

KDL-980EU

Filling, Stoppering & Pre-Closing Machine

|

GENERAL:

Kwang

Dah accumulated a lot of producing experience in liquid

filling, stoppering & closing machine for many years. We

developed the In-Line Aseptic Preparation Machine which is

designed for vials & eye-drops.

FEATURES:

|

|

4. |

The special fence is designed for reject the falling down bottles automatically before get into star wheel to make the production process more smoothly.

|

|

|

5. |

Equipped 2 separate star wheels in front & rear of the center working star wheel to ensure the bottles in & out smoothly.

|

|

|

6. |

The bottles transfer guide & star wheel are made from engineering plastic & they are easy to clean & change over without any tooling to achieve high efficiency of production operation.

|

|

| 7. |

It equipped 12 precision servo motors to enable the function of filling, stoppering, pre-closing & reject device more accuracy.

|

|

| 8. |

Two stages filling system prevents liquid spilling out during high speed filling.

|

|

| 9. |

The filling volume

(piston stroke) controlled by servo motor, it can fine

adjust for volume.

|

|

| 10. |

The liquid filler can fill the liquid from bottom of bottle with gradual upward movement to prevent liquid spills out and the forming of foam.

|

|

| 11. |

It adopted the servo motor for filling nozzle upward & downward, it can be adjusted the speed of upward for different products.

|

|

| 12. |

It adopted the mechanical design with servo motor to grab the stopper or rubber stopper into bottles precisely.

|

|

| 13. |

It adopted the mechanical design with servo motor to grab caps on the bottles precisely. It is convenient for operating & adjusting.

|

|

| 14. |

It equipped pre-closing device to avoid the cap falling down during transporting & avoid the contamination from generated the dust due to the friction during tighten the cap.

|

|

| 15. |

Equipped with a torque limiter under the center working star wheel, in case of crash on the star wheel, machine will stop automatically to protect the index device.

|

|

| 16. |

The filling piston & cylinder are 316 stainless steel, both piston and cylinder are one-piece machining made without welding to ensure clean & no residue remains.

|

|

| 17. |

The piston & cylinder are hard chrome plating & precision polishing for increase the filling accuracy & life time.

|

|

| 18. |

In order to achieve Aseptic Preparation standard, it equipped the isolation section for supplement the stopper during production to avoid the external sources of contamination into the clean area.

|

|

| 19. |

It equipped the automatic supplement caps device to keep away the possibility of causing contamination for supplement caps manually.

|

|

| 20. |

All contact with liquid material parts can be executed 121oC sterilization procedure over 40 minutes.

|

|

| 21. |

This machine is

controlled by PLC, it can detect the products & function as

below:

|

|

| 22. |

Adopt transparent safety guard (made of glass or PC material) & specifically designed for isolation gloves (Option) to prevent the contaminated.

|

|

| 23. |

The machines can be

equipped with laminar air flow for operations requiring a

particle-free and

|

|

| 24. |

Nitrogen can be filled before or after liquid filling. (Option)

|

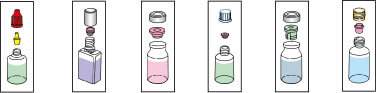

Application:

The operation sequence & description of stations:

.jpg)

.jpg)