|

|

KDY-FBD

Fluid-bed Spray Granulator / Dryer

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

GENERAL: |

||

|

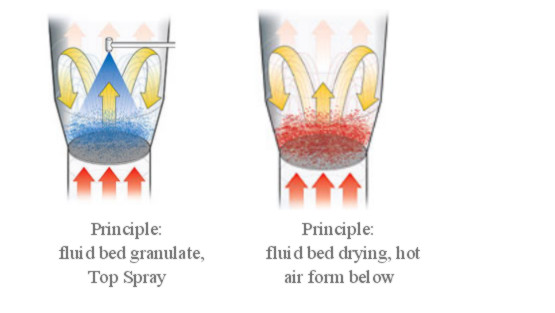

For Dryer / Granulation in batch mode, the dry starting product is placed in the product container. Here it is mixed vigorously in the heated gas stream, held in suspension and agglomerated/granulated by spraying with a suitable bonding material. The product is then dried to the required end moisture content with high heat and material transition coefficients. |

||

|

• |

Particularly fast drying even of temperature-sensitive products. |

|

|

• |

Very effective type of solid drying. |

|

|

• |

Outstanding heat transfer. |

|

|

•

|

Unmatched speed of drying. | |

|

•

|

Gentle product handling. | |

|

•

|

Intensive mixing of the solid material. | |

|

•

|

Uniform, reproducible product quality. | |

|

•

|

Homogeneous granules. | |

|

•

|

Gentle product handling. | |

|

•

|

Uniform spraying of all particles in the fluid bed. | |

|

|

||

|

ADVANTAGES: |

||

|

1. |

Mixing → Granulation → Drying Consistent operation. |

|

|

2. |

Grain size randomly adjustable subject to a wide variety of needs. | |

|

3.

|

Fast grain making without any damage to product effectiveness and flavor. | |

|

4.

|

Grains with perforated dispersion and high flow ability to make solution easy. | |

|

5.

|

Machine main body made of stainless steel , surface polished to make washing clean easy. | |

|

6.

|

Filter bags made of special conductive fiber effectively to eliminate statices and prevent spark discharge. | |

|

7.

|

Explosion relief hole to be mounted on top side of machine subject to the need of factory site. | |

| 8. | Filter bag timing shaking device to ensure effective drop of attachments from filter bags through shaking force. | |

| 9. | Fresh air filtered through high efficiency air filter. | |

| 10. |

Spray gun easy for angle adjustment , randomly adjusting spraying pattern air volume , during operation. |

|

|

FUNCTION: |

|||||||||||||||||||||||||||||||||||

|

◆ |

Drying: drying for powder or granule which contains moisture. |

||||||||||||||||||||||||||||||||||

|

|

◆ |

Granulating / Drying: spray binder or active ingredients on tiny powder to combine in granules, drying until required moisture content. |

|||||||||||||||||||||||||||||||||

|

FEATURES: |

|||||||||||||||||||||||||||||||||||

|

◎ |

Container |

||||||||||||||||||||||||||||||||||

|

|

• |

Contact parts AISI 316 non contact parts AISI 304. |

|||||||||||||||||||||||||||||||||

|

|

• |

Multi-pore bottom plate and stainless steel net. |

|||||||||||||||||||||||||||||||||

|

|

• |

With 4 freely movable casters. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 sight window for observation of work item flow. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 sample taker to remote specimen for checking during operation without stopping the unit. |

|||||||||||||||||||||||||||||||||

|

◎ |

Unit body |

||||||||||||||||||||||||||||||||||

|

|

• |

Contact parts AISI 316 non contact parts AISI 304. |

|||||||||||||||||||||||||||||||||

|

|

• |

2 operation holes with sight window. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 blast release vent. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 silicone gasket. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 container air-tight silicone lifter it is avoid use the cylinder makes in-convenience of cleaning. |

|||||||||||||||||||||||||||||||||

|

◎ |

Filter bag |

||||||||||||||||||||||||||||||||||

|

|

• |

Woven of specific cloths of conductive fibers with grounding to keep out static and spark discharge. |

|||||||||||||||||||||||||||||||||

|

|

• |

Automatic shaking device. |

|||||||||||||||||||||||||||||||||

|

|

• |

Filter bag with lifter. |

|||||||||||||||||||||||||||||||||

|

|

• |

1 silicone tire for air-tight filter bag. |

|||||||||||||||||||||||||||||||||

|

|

◎ |

Air exhaustion |

|||||||||||||||||||||||||||||||||

|

|

|

• |

1 set of exhaust fan. |

||||||||||||||||||||||||||||||||

|

|

|

• |

1 set of exhaustion damper of pneumatic operation to control air volume at no stage. |

||||||||||||||||||||||||||||||||

|

|

◎ |

Heating system |

|||||||||||||||||||||||||||||||||

|

|

|

• |

Regular steam heater of high efficiency and accurate temperature control. |

||||||||||||||||||||||||||||||||

|

◎ |

Automatic control |

||||||||||||||||||||||||||||||||||

|

|

• |

1 Ground type control box. |

|||||||||||||||||||||||||||||||||

|

|

• |

Digital automatic temperature controller for accurate hot air temperature control. |

|||||||||||||||||||||||||||||||||

|

|

• |

Automatic shaking of filter bag at pre-set timing. |

|||||||||||||||||||||||||||||||||

|

|

• |

1exhaust temperature controller. |

|||||||||||||||||||||||||||||||||

|

APPLICATION: |

|||||||||||||||||||||||||||||||||||

|

• |

Pharmaceutical a. Western medicine: granulating, drying b. Chinese medicine: granulating of concentrated liquid, drying. |

||||||||||||||||||||||||||||||||||

|

• |

Food Instant food: Health food, coffee, fruit favored milk powder, instant juice powder, seasoning, jelly powder, pudding powder, food additive. |

||||||||||||||||||||||||||||||||||

|

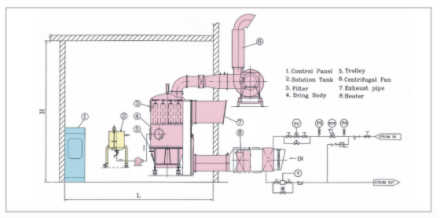

FLOWCHART:

TECHNICAL DATE:

|

|||||||||||||||||||||||||||||||||||